If you run an energy manufacturing factory, you have just a handful of variables that present options for cost-cutting and energy saving. Chief among them is energy use.

Energy conservation saves money. This fact isn’t new. what’s new is that the IoT.

Lots of effort is put into saving energy—use of motion-sensitive bulbs, limited time use of air conditioners, and cutting the number of shifts and functioning hours are some examples. But those actions require productivity/OEE boosting focus of the power and affect energy conservation.

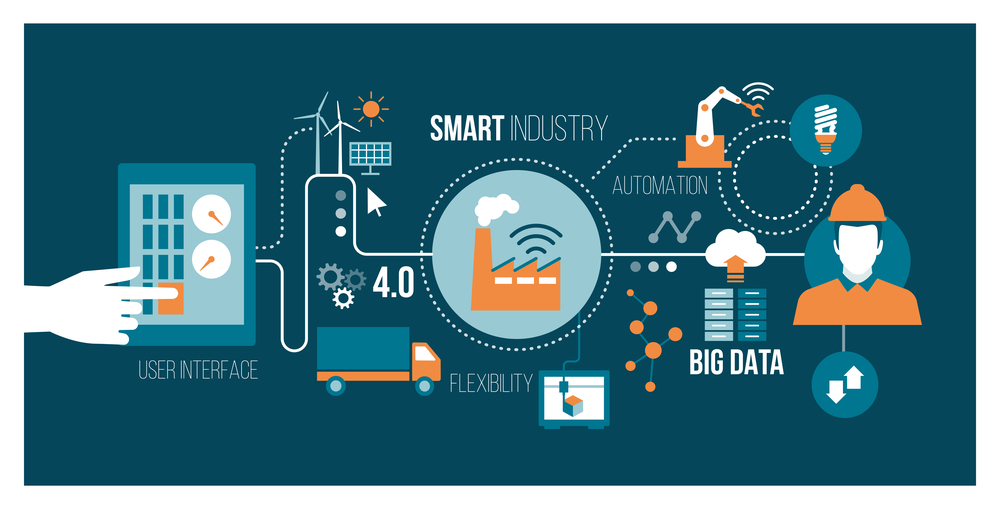

In addition, the Internet of Things (IoT), on the other hand, can enable direct energy savings for the smart factory of today.

Many professionals recommend IoT-based real-time monitoring systems to bring optimum use of energy. Real-time monitoring helps you track energy consumption, but that might not lead directly to energy conservation. For that, the real-time energy monitoring should lead to better forecasts of energy usage and become a guide to executing the right load-level energy equipment.

Two Components of Electrical Energy Billing:

Let’s take an example of electricity. Usually, electricity billing has two components: Demand Controller and Runtime/Consumption-related Charges. Demand load is usually the pack load provided by the electricity service providers from the power grid. This usually features a hard and fast limit. Crossing it’ll prompt penalties of around 20 times the standard rates.

Avoiding this setup often comes down to two options: reduce the entire energy load required by the machinery, or make sure that the edge limit is never reached.

The Problem of Motors and HVAC Systems:

One major source of electricity usage in the plant/factory/industry involves electrical motors, and HVAC systems. A motor is considered under-loaded when it’s in the range where efficiency drops significantly with the decreasing energy load. Most electric motors are designed to run at 50% to 100% of rated load. Maximum efficiency is usually near 75%. Drop below the five hundred rated loads, and therefore the efficiency tends to lower intensely.

In many cases, operating motors are either overloaded, leading to overheating, or under-loaded, performing at most at 40% of their capacity. That causes huge spikes in energy consumption. Oversized motors have a better initial cost and are very expensive to repair and maintain. Undersized motors don’t perform well and prompt higher losses than properly sized electric motors. An equivalent goes for air conditioners. If their capacity and room size or room dynamics aren’t suitable, it results in higher energy consumption.

Addressing a Wide Range of Energy Consumers:

Apart from regular electrical consumption of motors and HVAC, IoT can address numerous energy sources and resources. These include:

- Air compressors—the source of air across plant.

- Boilers that serve as the main source of steam used across plants.

- Fuel, including diesel, coal, wood, solar, and batteries that are used to run above systems.

- Backup generators that provide an alternative electricity source in case of failure of the primary.

How IoT Can Help:

In the pre-IoT era, the normal energy-management system would collect a sample of energy usage at an interlude. the normal system is good to desire energy-consumption data, but it doesn’t assist you with alerts just in case of spikes, curating usage pattern, predicting the seasonal demand, or suggesting appropriate configuration.

With the IoT in place, the analyses can occur on real-time data from the motor. That makes the analysis quick, and more accurate. IoT brings real-time alerts, the ability to predict energy demand, usage patterns, and ways to optimize energy consumption.

With the proper IoT platform, you can recommend the right sizing needed for motors, thus saving money on the first investment. IoT-based conditional monitoring ensures the motor never reaches its threshold limit, which suggests the motor lasts longer and suffers fewer failures.